This Machine does Plasma Transferred Arc Welding process designed for general purpose, multi-faceted, hard face production welding.

FEATURES:

FEATURES:

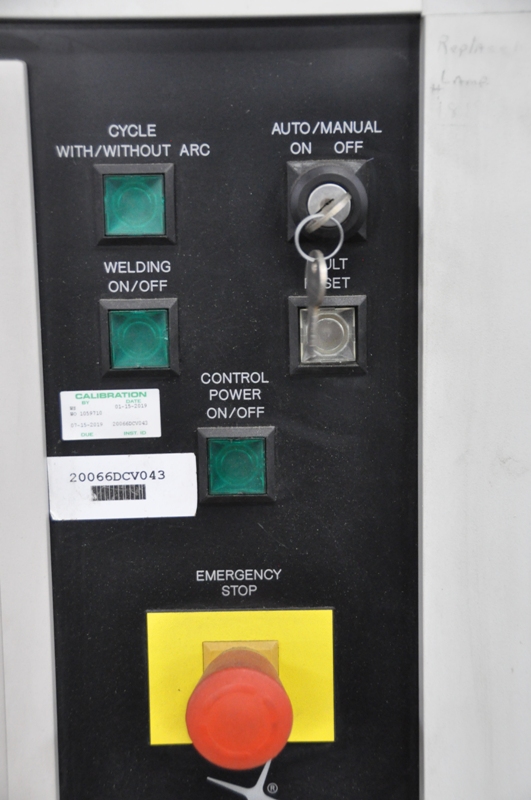

Dual Type Power Supply Requiring 480 Volts, 3 Phase, 48 Amps

Pilot Arc Output: 10 - 100 Amps Variable

Continuous Pilot Arc Output: 100% Duty Cycle @ 40 deg C

Transfer/Main Arc Output: 15 - 300 Amps

Transferred Arc: 100% Duty Cycle at @ 40 deg C

Water Chiller Unit is a closed loop, constant temperature, water refrigeration system. It is located in the power supply console.

Cooling Capacity (Based on water at 85 deg F): 15,000 BTUs, Temperature Stability: plus minus 2 deg F

Coolant Reservoir Capacity: 15 Gallon (Use Distilled or De-ionized Water Only.)

Torch Specifications:

Current Capacity: 20 - 250 amp

Pilot Current: 30

Deposition Rate: 1 - 80 grams/min

Tungsten Electrode: 1/8 in - 3/16 in

Plasma Nozzle: 1/8 in - 3/16 in

Cooling Requirements: 0.6 - 1.1 gpm

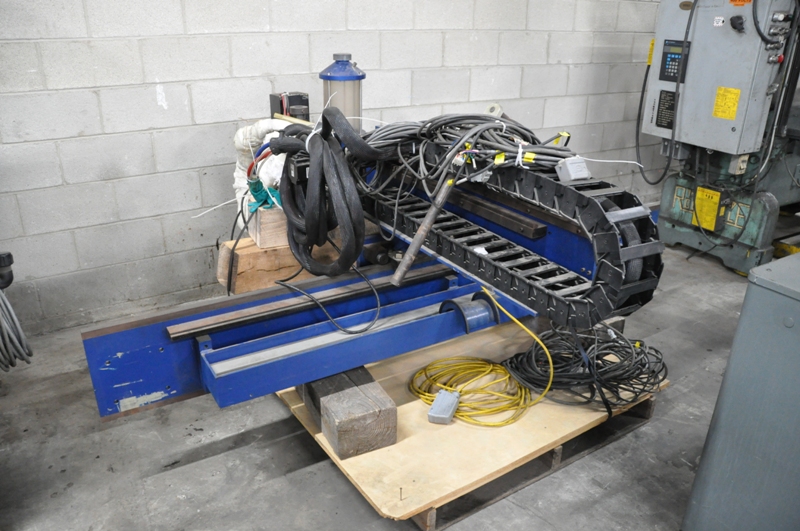

Carriage Manipulator:

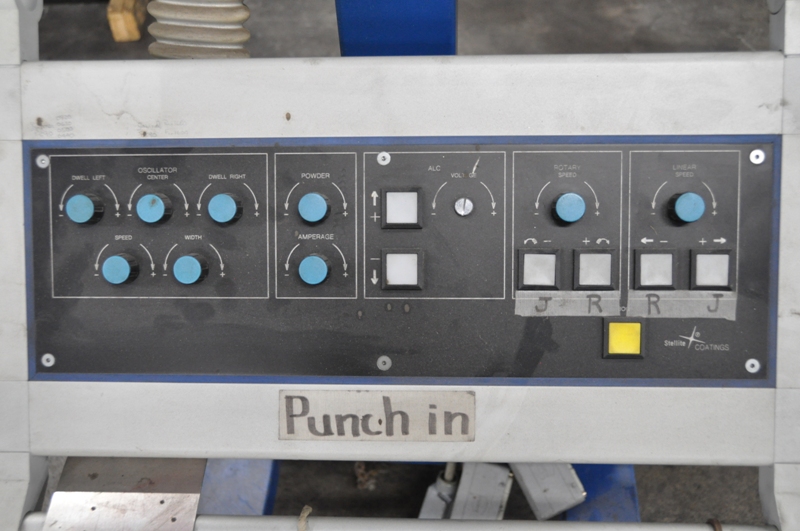

The 2-axis programmable motion of the optional Carriage Manipulator and Table allow the operator to hardface a wide range of parts including cylindrical parts such as shafts. The carriage manipulator is used to position the torch, powder feeder and oscillator on the beam assembly. The unit has a speed range of .01 - 10 inches per minute.

IN GENERAL:

2-Axis Starweld Welding System

Welding Modes: Spiral, Step Over, Linear, Rotary Oscillation, Step Over

Model 600 Torch Assembly

KK-2 Powder Feeder Assembly

EQUIPPED WITH:

Koike Aronson Welding Positioner, 2,500 Lb. Capacity, Serial #40371, Model 25P

32" Diameter Table with Power Tilt and Rotation and Manual Elevation Adjustment

40-1/2 "Floor to Centerline of Positioner Table When in the Vertical Position

Pendant Control of Welding Positioner for E Stop and Tilt Only, Variable Rotation Speed

Controlled via Stellite System

Positioner Table Tilts 0 to 140 Degrees, Rotates 360 Degrees

OEM Operation Manuals, Drawings, Schematics, etc.

Torch Gases Required But NOT Supplied

Water Chiller Unit Required But NOT Supplied

Overall Size of Components:

Stellite Control: 36 in LR x 60 in FB x 68 in High x ? Lbs.

Rail with Torch Unit: 96 in LR x 87 in FB x 48 in High x ? Lbs.

Welding Positioner: 51 in LR x 62 in FB x 62 in High x ? Lbs.

Operators Console: 27 in LR x 27 in FB x 58 in High x ? Lbs.

(2) Rail Posts: 16 in LR x 20 in FB x 68 in High x ? Lbs.

Installation: http://www.hildebrandmachinery.com/19096-installation.pdf

Operation: http://www.hildebrandmachinery.com/19096-operation.pdf

Stellite Torchhttp://www.hildebrandmachinery.com/19096-torch.pdf

Programming: http://www.hildebrandmachinery.com/19096-programming.pdf

Electrical Drawing 1: http://www.hildebrandmachinery.com/19096-drawing1.pdf

Electrical Drawing 2: http://www.hildebrandmachinery.com/19096-drawing2.pdf

To view more information on the STELLITE STARWELD WELDING SYSTEM WITH KOIKE ARONSON WELDING POSITIONER, including reviews, brand information, photos, videos, and more,

Fill in the form below to see Seller Info.