MACHINE TOOL ASSOCIATES, INC PROPOSAL

145 Brindle Rd., Mechanicsburg, PA 17055 Phone: 717-586-4672

E-Mail: harleyboy@comcast.net Web: www.Machinetoolassociates.com

Stock Number: 21240

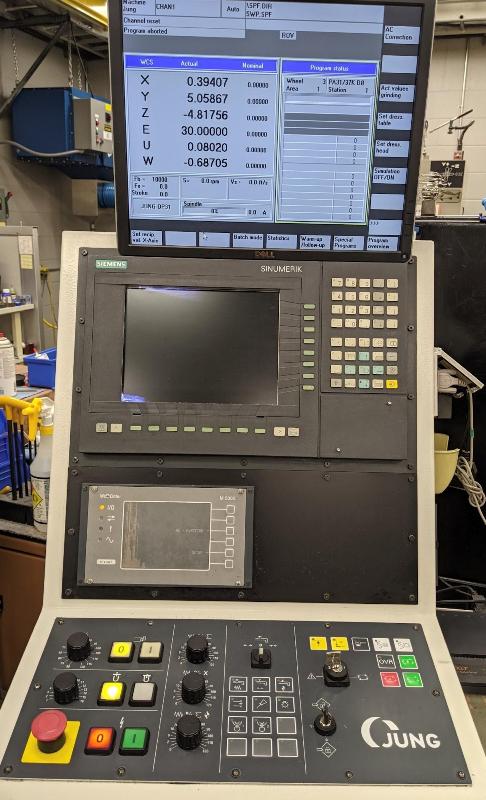

USED 2002 JUNG CNC SURFACE AND CONTOUR GRINDING MACHINE

MODEL J 630 D

Grinding area (L x W) 600 x 305 mm

S/N 1367

TECHNICAL DATA

WORKING AREA

Table working surface ( l x w ) 23.622 in x 9.842 in

Grindable surface (including wheel width 25 mm) 23.622 in x 12.007 in

Size of magnetic chuck 24 in x 12 in

Maximum distance between top edge of table and spindle center (Y) 19.291 in

Maximum table load (including magnetic chuck) 260 lbs

GRINDING WHEEL

Diameter 11.811 in

Width 1.181 in

Bore hole 3.000 in

Radial wear 1.772 in

GRINDING SPINDLE

Input power 13.410 HP

Maximum cutting speed 115 ft/sec

Mounting taper 1:10

MACHINE AXES

X-AXIS (horizontal motion, longitudinal)

Traversing speed, Reciprocal Grinding

(hydraulic, steplessly adjustable) 39.370~944.881 in/min

Traversing speed, deep Creepfeed grinding

(with AC servo motor) 0.197~39.370 in/min

Traverse path between limit switches 24.803 in

effective reciprocating stroke 24.803 in

Y-AXIS (vertical motion)

Traversing speed 0.004~78.740 in/min

traverse path between limit switches 14.083 in

axis resolution / input resolution: see description of controls

Z-AXIS (horizontal motion, cross)

Traversing speed 0.004~78.740 in/min

Traverse path between limit switches 10.945 in

axis resolution / input resolution: see description of controls

INSTALLATION AND ELECTRICAL DATA

Machine width 118 in

Machine depth (without control panel or control cubicle) 106 in

Machine height (depending on equipment) 96 in

Weight (machine without casing or control cubicle) 5512 lbs

Weight (machine with ordinary casing and control cubicle) 7055 lbs

Operating voltage VAC / Hz 400 / 50

Control voltage VAC 230

Control voltage VDC 24

Total power requirement with grinding power 13.5 HP

Fuse protection A 35

MACHINE CONTROL

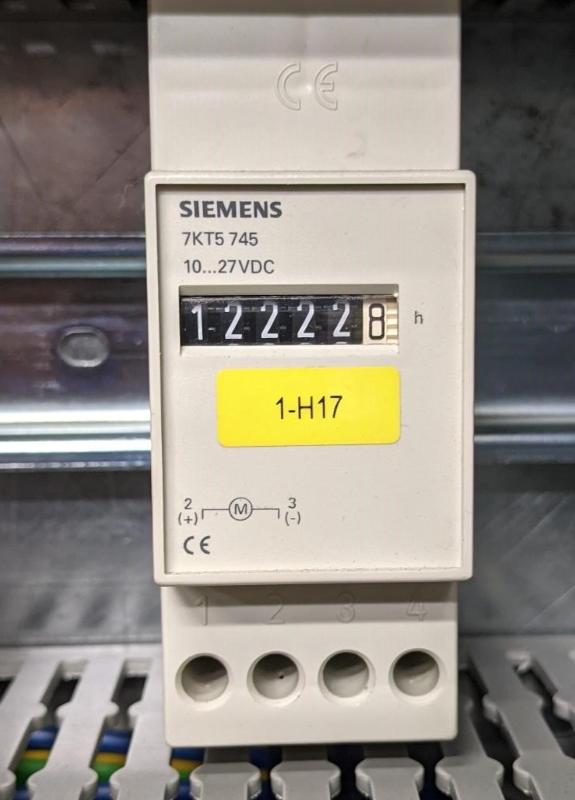

SIEMENS 840D CONTROL

Control panel with 10.4 in TFT flat screen, color

Digital drive technique for the machine axes, basic equipment 3 axes + 1 grinding spindle, further axes can be integrated

Program management

Automatic, electric brake for grinding spindle drive

4-quadrant DC drive, variable speed 800 to 4200 RPM, prepared for Modem-connection for online diagnostics

CONTROL FEATURES

Control in accordance with type designation

Reciprocal surface grinding, 1 surface

Continuous feed

Grinding infeed on one or both sides

Reciprocal surface grinding, 1 surface

Intermittent feed on one or both sides

Grinding infeed on one or both sides

Reciprocal plunge grinding, 1 groove

Grinding infeed on one or both sides

Cylindrical peripheral dressing from table

Automatically compensation of dressing dimension

Tool management consisting of 1 grinding wheel and 1 dressing set

Menu-guided technology programming infeed values, feed rates, allowances, gauge blocks, peripheral speeds, sparking-out strokes, dressing cycles and intervals

Modification of technology during machining

Input / output of programs via V24 / RS232C

Programming during machining

Linear scales for vertical and transverse axes

Jung remote control panel with electronic handwheel, readout of actual position and control elements

for all manual functions

Grinding spindle drive DC motor, 10 kW output

Vertical and transverse axes with servo motor and ball screw in closed position control loop

Automatic central lubrication unit for screws and column table and cross-slide guides

1 grinding wheel flange

INCLUDED ACCESSORIES

A-PA31K Automatic profile dressing tool with 4 diamond-changing device comprising:

Dressing tool with turret head for 4 single diamonds.

Dressing arm integrated in cover

Setting device with dial gauge (0.001 mm) for aligning dressing diamonds

4 diamond holders for dressing diamonds (shank diameter 9.25 mm)

TECHNICAL DATA

Dressing range: 50 mm

Profile width: 15 to 20 mm

Profile depth, inside / outside: plus/minus 0.0025

Traverse paths:

W axis 55 mm

U axis 60 mm

E axis plus/minus 45 degrees

Maximum dressing speed 1000 mm/min

Hydraulic fluid Chiller for:

high ambient temperatures

short stroke

for use with creepfeed

transverse positioning

Coolant purification system with flushing valve for deep grinding comprising:

Coolant tank with band filter system, filter paper, coolant pipes, coolant outlet, rubber splash protection.

Addition of NS-KA450 is possible.

Dimensions L/W/H 2170/820/800 mm

Height of inlet 565 mm

Filter capacity 150 l/min.

Tank capacity 450 l/max.

Filter paper width 710 mm

Delivery rates:

Creepfeed pump l/min. 70 at 3.5 bar

Discharge flow rate at nozzle l/min. 100

Grinding/dressing pump l/min. 70 at 0.2 bar

Discharge flow rate at nozzle l/min. 25

Isolating transformer for connected electrical loads other than 400 V / 50 Hz or 400 V / 60 Hz

Electro-permanent magnetic chuck, manufactured by Jung, with continuous cross-pole graduation, longitudinal stop bar.

Magnetic potential 210 V

Supply voltage 400 V

Clamping surface mm 600 x 250

Full enclosure of working area. Z-axis travel is reduced by 10mm.

Documentation, including:

operating instructions

electrical wiring diagram

SPS program print

list of electrical parts

list of spare parts and of parts for wear and tear

Deep grinding with AC control (creepfeed grinding) including automatic adjustment of the cutting power during creepfeed grinding for optimizing the grinding process. The table feed rate is adjusted according to the cutting performance. The feed rate is steplessly adjustable. Creepfeed programs for up and down-grinding with integrated operator guidance.

Grinding mist collector, comprising of:

air filter, type SNA20

surface area 20 m3/min

motor output 0.75 kW, 1.8 A

voltage 400 V 3 Ph, 50 Hz

percentage purity 99.9%

By use of CNC machines switchable by program.

Complete set HSK: 1 spindle, 1 flange, 1 clamping device. Z-zero clamping system based on hollow shank taper, clamp for grinding wheels, ultra-precise positioning in the Z and Y directions when the

grinding wheel is changed.

Grinding wheel flange HSK40. Z-zero clamping system based on hollow shank taper, clamp for grinding wheels, ultra-precise positioning in the Z and Y directions when the grinding wheel is changed.

Network connection for control Siemens 840 D, consisting of hardware adapter for control, network card and system software.

Vector CAD module for individual input of geometries (qualification G-SG32) with functions consisting of input of geometries, manipulation of geometries (rotate, reflect, etc.) and linking to GRIPS 32.

Warm-up / run-off program with time switch function for starting up and shutting down the machine automatically

start function: spindle ON, coolant ON

X-axis reciprocates, Z-axis reciprocates

run-off function: spindle runs for defined time period

programmable: date and time (date selectable ON / OFF)

Tool management for 100 grinding wheels enlargement and 30 dressing diamond sets.

G-Batch programming.

Automatic transverse positioning with 999 uniformly spaced divisions, each with the same depth and 40 irregularly spaced divisions with different depths.

Automatic reciprocal face grinding with selectable wheel edges (left or right).

Grinding program for CNC path grinding in the transverse direction (Z/Y).

Grinding program for CNC path grinding in the longitudinal direction (X/Y).

Continuous dressing of the grinding wheel during the machining process, both for creepfeed grinding and for reciprocating during roughing.

Continuous feed (Y-axis) / plunge grinding with stationary table (X-axis).

END OF SPEC

To view more information on the JUNG CNC SURFACE AND CONTOUR GRINDING MACHINE, including reviews, brand information, photos, videos, and more,

Fill in the form below to see Seller Info.