Description:

1-USED GENESIS SYSTEMS GROUP DUAL ARM FANUC ARCMATE 100iC MIG WELDING CELL

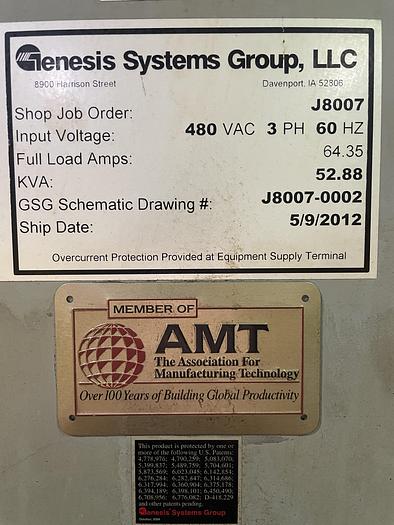

SERIAL NUMBER ON GENESIS CELL J8007

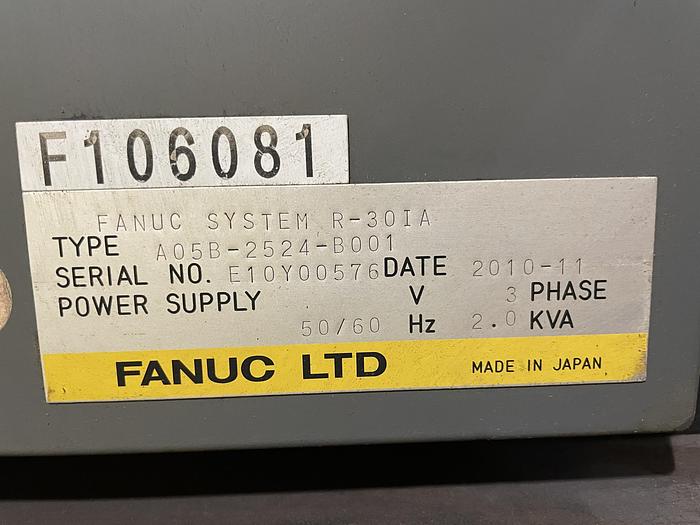

SERIAL NUMBERS ON ROBOTS IN CELL F106081 & F106082

CELL DATE OF MFG. 2012

STK#104869

==================================

SPECIFICATIONS WHILE OBTAINED FROM SOURCES DEEMED

RELIABLE ARE SUBJECT TO CHANGE WITHOUT NOTICE

AND TO VERIFICATION BY BUYER:

THIS IS A GENESIS SYSTEMS GROUP ROBOTIC MIG WELDING CELL WITH TWO

FANUC ARC MATE 100iC ROBOTS, SMALLER COMPACT FANUC R30iA CONTROLLERS,

TWO MILLER AUTO-AXCESS 450-DI WELDING POWER SUPPLIES, MILLER WIRE FEEDERS,

WELD GUNS, TIP REAMER, 60" DIAMETER A/B SIDED INDEX TABLE. ENCLOSURE PANELS.

THE CELL IN 2 MAIN FABRICATED COMPONENT BASES. ONE BASE IS FOR THE 2 FANUC

ARC MATE 100iC ROBOTS AND THE 60" INDEX TABLE. THE OTHER FABRICATED BASE

PROVIDES A SPACE FOR THE TWO FANUC R30iA ROBOT CONTROLLERS AND THE

TWO MILLER AUTO-AXCESS 450-DI WELDING POWER SUPPLIES. THERE IS A SKID

THE ENCLOSURE WALLS FOR THE CELL WITH LIGHT CURTAINS.

The Fanuc ARC Mate 100iC is a 6 axis robot designed to provide maximum performance and reliability for welding and cutting applications. The 100iC protects the weld torch cable, gas lines, air lines, and the wire feeder motor cable by routing them inside the robot arm. This improves reliability and reduces setup time, prevents cable interference, and allows offline program generation without compromising the cable integrity.

The 100iC robot creates a large work area and maintains high speeds throughout, conquering up to 10 kg of payload, all the while using a slim wrist enabling entry into small openings in the work space. In addition, this robot arm moves 15% faster than the other robots in its class and can process large parts and use complex tooling without compromising productivity. The Fanuc ARC Mate 100iC is compatible with all major brands of welding equipment and can be interfaced with most types of servo-driven or indexing positioners.

A huge advantage of the ARC Mate 100iC is that it is equipped to see, sense, and simulate with the software pair of iRVision system and Collision Guard. Programming is also faster and simpler with a ROBOTGUIDE-WeldPRO simulation software package and Vision Shift that helps compensate for gaps in product spacing during arc or spot welding. Both allow for seamless tooling and fixture changes, ultimately eliminating accidents and saving time normally spent testing or adding adjustments.

ROBOT SPECIFICATIONS (2 UNITS IN CELL):

Axes: 6

Payload: 10kg

H-Reach: 1420mm

Repeatability: Plus/minus 0.08mm

Robot Mass: 130kg

Structure: Articulated

Mounting: Floor, Inverted, Angle

Robot Motion Speed:

J1 210 deg/s (3.67 rad/s)

J2 190 deg/s (3.32 rad/s)

J3 210 deg/s (3.67 rad/s)

J4 400 deg/s (6.98 rad/s)

J5 400 deg/s (6.98 rad/s)

J6 600 deg/s (10.47 rad/s)

Robot Motion Range:

J1 Plus/minus 360 deg

J2 Plus/minus 250 deg

J3 Plus/minus 447 deg

J4 Plus/minus 380 deg

J5 +380 deg to 280 deg

J6 +720 deg to 540 deg

Applications:

Arc Welding Robots

Laser Welding Robots

MAG Welding Robots

MIG Welding Robots

Orbital Welding Robots

Oxyacetylene Welding Robots

Plasma Cutting Robots

Plasma Welding Robots

Submerged Arc Welding Robots

TIG Welding Robots

EQUIPPED WITH:

2 FANUC ARCMATE 100iC MIG WELDING ROBOTS

2 FANUC R30iA ROBOT CONTROLLERS

2 MILLER AUTO-AXCESS 450-DI WELDING POWER SUPPLIES

60 in DIAMETER A/B SIDED INDEX TABLE

2 MILLER WIRE FEEDERS

2 WELDING TORCHEDS

1 TORCH TIP REAMER

FENCING GAURDING

FANUC ROBOT CONNECTION CABLES

ALLEN BRADLEY TOUCH SCREEM 1000 HMI

ALLEN PLC BRADLEY CONTROLS INTEGRATE THE CELL

MANUFACTURED BY GENESIS SYSTEMS GROUP

FOB TRUCK, 300 EAST SECOND STREET, IMLAY CITY, MI 48444

THIS ITEM IS OFFERED FOR SALE SUBJECT TO PRIOR SALE AND

BUYERS UNCONDITIONAL ACCEPTANCE OF SELLERS TERMS

AND CONDITIONS.

RAB INDUSTRIES, INC.

Specifications

Manufacturer FANUC

Model FANUC ARC MATE 100iC

Year 2012

Condition Used

Serial Number F106081 & F106082

Stock Number 104869

Axes 6

Payload 10kg

H-Reach 1420mm

Repeatability Plus/minus 0.08mm

Robot Mass 130kg

Structure Articulated

Mounting Floor, Inverted, Angle