Description:

INCLUDING:

DURMA STANDARD FEATURES

DURMA CAPACITIES AND SPECIFICATIONS

DURMA OPTIONAL ATTACHMENTS

PRODUCT LITERATURE

STANDARD FEATURES:

SYNCRO Y1Y2 AXES & CNC CONTROL MOTORIZED CROWNING

INDEPENDENT LEFT AND RIGHT AXES (Y1Y2) CONTROLLED BY ELECTRONICS SERVO VALVES & ELECTRONICS LINEAR POSITION CONTROLLERS.

CNC CONTROLLED MOTORIZED CROWNING SYSTEM HOMOGENIZES BENDING FORCES EVERY POINTS OF THE BENDING PARTS TO ACQUIRE STRAIGHTS BENDS. THE NEED FOR SHIMMING IS ELIMINATED.

ANY BENDING ANGLE CAN BE MEASURED.

VERY COMPACT, EVERYTHING IN THE APPLIANCE.

LIGHT INFLUENCE, LIGHT OR DARK MATERIAL SURFACES PLAY PRACTICALLY NO PART AT ALL.

SLIDING FRONT ARMS

QUICKSET SUPPORT ARMS ARE MOUNTED ON A LINEAR QUIDE WAY AND BALL BEARING SYSTEM THAT ALLOWS (FINGER-TIP) LATERAL ADJUSTMENT OF THE FRONT SUPPORT ARMS. VERTICALLY ADJUSTMENT IS ALSO EASILY ACHIEVED.

HIGH STROKE | DAYLIGHT | THROAT = HIGH WORKING SPACE

AD-S MACHINES OFFERS WIDE SPACES FOR EASE OF OPERATION ALSO REDUCES CYCLE TIMES.

X-R BACK GAUGE

FINGERS` DEPTH AND HEIGHT IS CALCULATED BY CNC CONTROLLER AND EXECUTES HIGH SPEED SERVO MOTORS PRODUCED BY SIEMENS. RETRACTION IS ALSO A STANDARD FEATURE TO ACQUIRE ACCURATE PARTS. BACK GAUGE FINGERS ARE EASILY ADJUSTED ON LINEAR GUIDES BY BALL INTEGRATED MOTION SYSTEM.

DA-66T:

THE NEW GENERATION DA-TOUCH CONTROLS OFFERS AN EVEN HIGHER GRADE OF EFFICIENCY IN PROGRAMMING, OPERATION AND CONTROL OF TODAYS PRESS BRAKES. EASE OF USE COMBINED WITH STATE-OF-THE-ART TECHNOLOGY GO HAND IN HAND, IMPROVING PRODUCTIVITY.

THE TOUCH SCREENGIVES ACCESS TO THE PROVEN DELEM USER-INTERFACE AND ENABLES DIRECT NAVIGATIONBETWEEN PROGRAMMING AND PRODUCTION. FUNCTIONS ARE DIRECTLY LOCATED WHERE YOU NEED THEM, OFFERING OPTIMISED ERGONOMICS THROUGHOUT THE APPLICATION.

THE DA-66T OFFERS 2D PROGRAMMING THAT INCLUDES AUTOMATIC BEND SEQUENCE CALCULATION AND COLLISION DETECTION. FULL 3D MACHINE SET-UP WITH MULTIPLE TOOL STATIONS GIVING TRUE FEEDBACK ON THE PRODUCT FEASIBILITY AND HANDLING.

HIGHLY EFFECTIVE CONTROL ALGORITHMS OPTIMISE THE MACHINE CYCLE AND MINIMISE SET-UP TIME. THIS MAKES USING PRESS BRAKES EASIER, MORE EFFICIENT AND MORE VERSATILE THEN EVER.

DA-66T FEATURES:

2D GRAPHICAL TOUCH SCREEN PROGRAMMING MODE

3D VISUALISATION IN SIMULATION AND

PRODUCTION

17" HIGH RESOLUTION COLOUR TFT

FULL WINDOWS APPLICATION SUITE

DELEM MODUSYS COMPATIBILITY (MODULE SCALABILITY AND ADAPTIVITY)

USB, PERIPHERAL INTERFACING

USER SPECIFIC APPLICATION SUPPORT WITHIN THE CONTROLLERS MULTITASKING ENVIRONMENT

SENSOR BENDING & CORRECTION INTERFACE

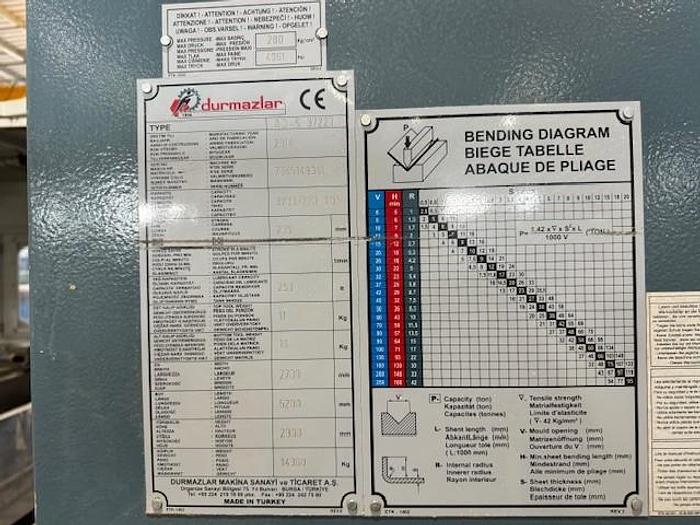

SPECIFICATIONS: INCH METRIC

BENDING FORCE 240 US TONS 220 METRIC TONS

BENDING LENGTH (A) 12 ft 1 in 3700 MM

DISTANCE BETWEEN COLUMNS (B) 10 ft 2 in 3100 MM

TABLE WIDTH (G) 4.1 in 104 MM

TABLE HEIGHT (F) 35.4 in 900 MM

APPROACH SPEED 282 in /MIN 120 MM/SEC

BENDING SPEED 24 in /MIN 10 MM/SEC

RETURN SPEED 236 in /MIN 100 MM/SEC

RAM REPEATABILITY .0004 in .01 MM

BACKGAUGE TRAVEL 25.6 in 650 MM

BACKGAUGE SPEED 1200 in /MIN 508 MM /SEC

STROKE (C) 10.4 in 265 MM

DAYLIGHT (D) 20.87 in 530 MM

THROAT DEPTH (E) 16.14 in 410 MM

MOTOR POWER 30 HP 22 KW

OIL TANK CAPACITY 66 GAL 250 LITRES

LENGTH (L) 16 ft 3 in 4950 MM

WIDTH (W) 5 ft 10 in 1770 MM

HEIGHT (H) 9 ft 6 in 2900 MM

WEIGHT 31592 LBS 14360 KG

STANDARD EQUIPMENT:

4 AXES CNC: Y1, Y2, X, & R AXIS WITH BACK GAUGE

CONTROL UNIT - CNC DELEM DA 66T - 2D COLOR GRAPHICS

UNIVERSAL WEDGE STYLE PUNCH CLAMP FOR AMERICAN OR EUROPEAN STYLE PUNCHES

SLIDING SHEET SUPPORT ARMS MOUNTED ON LINEAR RAIL WITH T-CANAL AND TILTING STOP

CNC CONTROLLED MOTORIZED CROWNING

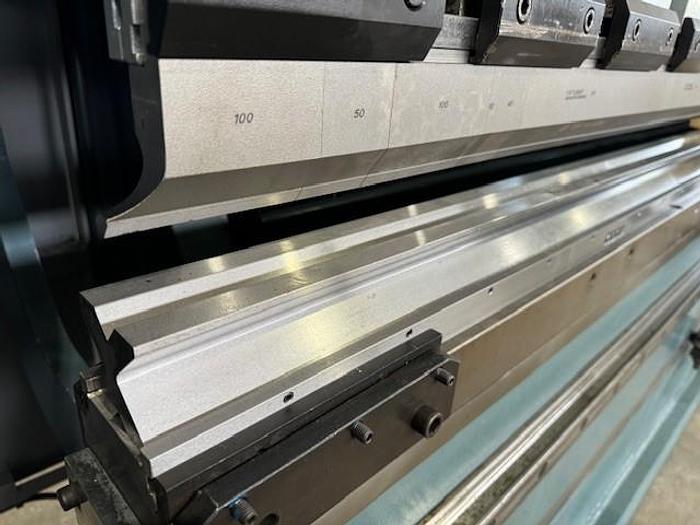

PRECISION GROUND SEGMENTED GOOSE NECK PUNCH, AND 4 WAY DIE

SINGLE V DIE HOLDER INSERT

LARGE OPEN HEIGHT, STROKE, AND THROAT DEPTHS STANDARD

WORLD CLASS HYDRAULICS BLOCKS & VALVES

WORLD CLASS ELECTRONICS SYSTEM

COMES WITH NEW TOOLING M.460R-4 WAY DIE P97.75.R08

Specifications:

Manufacturer DURMA

Model AD-S-37220

Year 2014

Condition Used

Serial Number 7345149041