Reference #: 6917

Machine Type: Deburring Machines

Year:

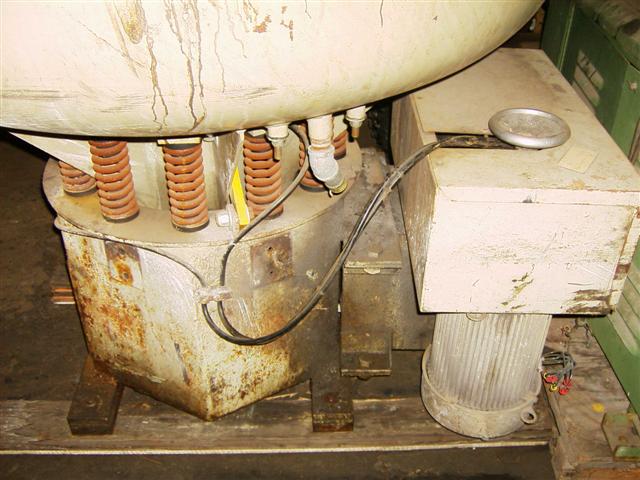

Manufacturer: Almco

Model: OR20VHE Round Bowl Vibratory Deburring Machine

Control:

Code: D0654

Specifications:

Working deburring capacity: 18 Cubic Feet

Length (overall including electric control box): 80"

Width (overall): 60"

Height (overall): 54"

Bowl:

Diameter: 60"

Cross Section: 17-1/2" (Diameter)

Lining (Thckness of Polyurethane): 1"

Comments:

New Style Almco Vari-Drive System

Center Dome Feature

Pedestal mounted control panel

Tub 17,5" cross section

Bowl Diameter 60"

The machine has been cleaned and is ready to be primed and painted

Power Unit:

10 hp, 1800 RPM totally enclosed, ball bearing motor for 230/460 volt (please

specify voltage), 3 phase, 60 cycle operation driving a variable pitch pulley.

The pulley is connected to two flat V-belts in a companion sheave on the

vibratory mechanism. Frequemcy of vibration is variable from 900 to 1400

cycles per minute by turning the handwheel on the motor base resulting in a

change in pulley pitch diameter. All moving drive componensts are well

guarding for operator protection.

General:

This High-Energy "OR" Series Machine is composed of the following basic

compoents:

(1) The support base and framework

(2) The Drive Unit

(3) Almco`s Natural Contour Molded Urethane Lined Tube

(4) The Vertical Shaft Vibrator

(5) The Electrical Control Enclosure

Description:

Discharge of parts and media from the round bowl is accomplished with a plug

type door with molding lining at one end of the bowl near the bottom periphery.

The door is equipped with a quick-acting, overcenter cam lock that assures a

positive seal when closed during processing. When the plug door is removed,

the parts and media flow from the bowl onto a heavy gauge steel chute that channels them to a

collection pan or conveyor.

The round bown is supported on the stationary framework of the machine on

heavy coil wound springs that serve to supplement the finishing motion of the

bowl and at the same time to eliminate finishing vibration from the stationary

framework.

Finishing motion of the round bowl is accomplished by adjustable counterweights

on the output shaft of a heavy duty vibratory mechanism equipped with self-aligning spherical

roller bearings that are mounted in a precision machined housing. The shaft of

the vibratory mechanism is driven by two V-belts running in a deep groove, off-set

sheave to eliminate shock loading and whip in the V-belts. A manual lubrication

system is provided to allow lubrication into the bearings of the vibratory

mechanism from the stationary base.

The machine is equipped with a water system designed to inject water into the

processing tub. The tub is equipped with two perforated (replaceable) molded

drain plates in the tub bottom to allow continuous flow of liquids in the vibratory

tub.

The electrical controls for the machine are in conformance to N.E.C. electirical

specifications with the motor operating on either 230 or 460 volt current and with

all operator controls on 110 volt current supplied by a transformer within the

control box. All necessary controls for the machine`s operation including

Automatic Reset Timer (adjustable time range) are housed in one NEMA type 12

panel enclosure mounted on a pedestal separate from the machine to allow

positioning the enclosure as needed.

To view more information on the ALMCO OR20VHE ROUND BOWL VIBRATORY DEBURRING MACHINE #6917, including reviews, brand information, photos, videos, and more,

Fill in the form below to see Seller Info.