Description:

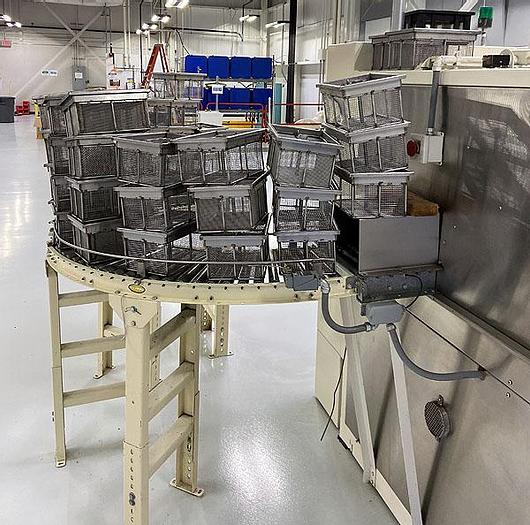

AUTOMATED VERTICAL AGITATING/ ROTATING CLEANING SYSTEM

This machine, as designed, will process one basket (maximum weight 45 pounds) at a time through the following stations:

Station #1: Programmed Power Feed Conveyor

Station #2: Alkaline Wash 140-160 F.

Station #3 Rinse 140-160 F.

Station #4: Rinse 140-160 F.

Station #5: Recirculating Hot Air Dry 120-250 F.

Station #6: Recirculating Hot Air Dry 120-250 F.

Station #7: Recirculating Hot Air Dry 120-250 F.

Station #8: Recirculating Hot Air Dry 120-250 F.

Station #9: Recirculating Hot Air Dry 120-250 F.

Station #10: Recirculating Hot Air Dry 120-250 F.

Station #11: Recirculating Hot Air Dry 120-250 F.

Station #12: Unload

APPROXIMATE MACHINE DIMENSIONS

Length: 14 with dryer

Width: 50" (less filtration & conveyors)

Height: 6-6" (less exhaust system)

Solution Capacity Per Tank - 60 gallons, approximate

BASKET SIZE

This system is designed to process work baskets with dimensions of up to 8.75" wide x 11.75" long x 6" high (not to exceed 45 pounds each).

GENERAL CONSTRUCTION PRACTICES

POWER FEED CONVEYOR FOR CARRIER OR BASKET LOADING

PUSHER TRANSFER

AGITATING MECHANISM

BASKET/CARRIER ROTATION MECHANISM

SOLUTION TANKS

TANKS:

Size: 26" wide x 24" long x 30" deep

Tanks: 11 gauge type 304 stainless steel, sloped bottoms, double welded with angle iron and I-beam support

Drain Size: 2" split nipple

Overflow Size: 1.5 " dam type

Level Control and Make Up: Protec conductance type with solenoid valve for coalescers and final rinse

Low Level Protection: Provided on each tank

Water Inlet: 3/4" from common header

Insulation: 2" fiberglass block, exterior surfaces, 14 gauge hot

Rolled outer skin

Rinse Tanks: All rinse tanks are equipped with counter flow water System Filter Fittings: Screened to protect pumps

Drain Header and Valves: CPVC with appropriate valves

ELECTRIC HEATING EQUIPMENT

Elements: Stainless steel, 3 element immersible

Ratings: Two hour heat up to 160 F. from ambient (55 F.)

Temperature Control: Process Technology digital temperature controller Each tank to have separate temperature control.

CFR - COUNTERFLOW FOR TANKS

SPARGERS

FILTERS

DOALESCING TYPE OIL SKIMMER SYSTEM

EXHAUST SYSTEM

RECIRCULATING HOT AIR DRYER

Fan Make: Chicago Blower

Capacity and Pressure: 3,700CFM at 2" S.P.

Motor: 5 HP, 1750 RPM, TEFCBB

Heat System: Electric heating elements,

Temperature Control: Process Technology digital temperature controller with safety shut off

Dryer Chamber: 14 gauge stainless steel with 14 gauge ducts

Enclosure: 14 gauge hot rolled steel

Insulation: 2" fiberglass block insulation covered with 14

gauge steel

DRYER ROTATION

GUARDS

ELECTRIC 208 VAC, 3 PHASE, 60 HZ

Specifications:

Manufacturer Jenfab

Model Jensen

Year 2002

Condition Used

Stock Number 3145